-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

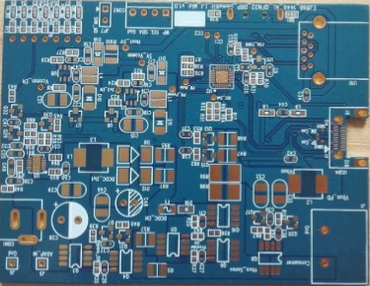

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

Featured Blogs

Precise Impedance Control through Layer Stackup Design

The foundation of effective impedance control lies in the meticulous design of the multilayer PCB's layer stackup. This involves carefully selecting the materials, thicknesses, and arrangement of each layer – including dielectric layers, copper traces, and ground planes – to achieve the target impedance. Sophisticated computer-aided design (CAD) software is employed to simulate and fine-tune the layer stackup, ensuring minimal deviation from the specified impedance value across the entire board. Careful consideration is given to the dielectric constant (Dk) and dissipation factor (Df) of the chosen materials, as these directly impact the impedance characteristics.

Furthermore, the controlled placement of ground planes within the stackup is crucial. Ground planes offer return paths for signals, reducing loop inductance and minimizing electromagnetic interference (EMI). Strategies like employing multiple ground planes, strategically placed via stitching, and controlled impedance controlled routing all contribute to achieving the desired impedance profile and enhanced signal integrity.

Advanced Manufacturing Processes for Impedance Consistency

Precise impedance control extends beyond design; the manufacturing process must maintain the intended characteristics. Advanced EMS techniques employ high-precision laser drilling for vias and controlled etching processes to ensure consistent trace dimensions and geometries. Any deviations from the designed dimensions can significantly alter the impedance, leading to signal integrity issues. Stringent quality control measures, including regular impedance testing at various stages of production, ensure consistency and adherence to specifications.

The use of specialized materials, such as low-Dk dielectric materials, is also critical. These materials minimize signal delay and reflection, contributing to higher data rates and better performance. High-quality copper foils ensure low resistance, minimizing signal attenuation and improving signal strength.

Automated Optical Inspection (AOI) and Impedance Testing

Automated Optical Inspection (AOI) systems play a vital role in ensuring the quality of the manufactured PCBs. AOI systems automatically scan the boards for any defects, including variations in trace width, spacing, and via placement, which can affect impedance. Early detection and correction of these defects are crucial for maintaining impedance consistency across the entire production run.

Furthermore, rigorous impedance testing is crucial throughout the manufacturing process. This involves using specialized equipment to measure the actual impedance of the PCB at various points, ensuring that it aligns with the design specifications. This iterative testing and adjustment, combined with the precision offered by advanced manufacturing techniques, results in a consistently high-performance product.

Conclusion

Efficient impedance control in multilayer PCBs is a multifaceted challenge requiring advanced EMS techniques. Through meticulous design, precise manufacturing processes, and rigorous quality control measures, EMS providers are able to deliver high-performance PCBs that meet the demanding requirements of modern electronic applications. The combination of sophisticated CAD tools, advanced materials, and automated inspection and testing ensures not only accurate impedance but also enhanced signal integrity, leading to improved performance, reduced signal loss, and minimized EMI, ultimately contributing to the success of countless electronic devices.

-

Flat Flexible Cable Innovations in Military Avionics Circuitry

Flat Flexible Cable (FFC) innovations have revolutionized military avionics circuitry, offering unparalleled advantages in terms of weight reduction, space efficiency, and reliability. As modern military aircraft become increasingly sophisticated, the demand for advanced circuitry solutions has never been higher. FFCs, with their thin, lightweight, and flexible design, have emerged as a game-changer in this domain. These cables are not only capable of transmitting high-speed data and power but also withstand the harsh environments typical of military operations. This article delves into the transformative role of FFCs in military avionics, exploring their benefits, applications, and future potential.

Enhanced Durability and Reliability

Military avionics systems operate in extreme conditions, including high temperatures, vibrations, and electromagnetic interference (EMI). Traditional wiring solutions often fail under such stress, leading to system failures. FFCs, however, are designed to endure these challenges. Their robust construction, often using high-temperature polyimide materials, ensures they remain functional even in the harshest environments.

Moreover, FFCs are resistant to corrosion and moisture, which are common issues in military aircraft. The absence of bulky insulation reduces the risk of damage from friction and abrasion. This reliability is critical in mission-critical systems where failure is not an option. By integrating FFCs, military avionics can achieve higher operational readiness and reduced maintenance costs.

Space and Weight Efficiency

One of the most significant advantages of FFCs is their ability to save space and reduce weight. Military aircraft are constantly striving to minimize weight to enhance performance and fuel efficiency. Traditional wiring harnesses are heavy and occupy considerable space, limiting design flexibility.

FFCs, on the other hand, are incredibly thin and lightweight. Their flat design allows them to be routed through tight spaces, enabling more compact and efficient avionics layouts. This space-saving feature is particularly valuable in modern aircraft, where every cubic inch counts. By replacing conventional wiring with FFCs, manufacturers can achieve significant weight reductions, leading to improved aircraft performance and payload capacity.

High-Speed Data Transmission

Modern military avionics systems rely on high-speed data transmission for real-time communication, navigation, and targeting. FFCs are engineered to support high-frequency signals with minimal signal loss, making them ideal for these applications. Their uniform conductor spacing and impedance control ensure consistent performance, even at high speeds.

Additionally, FFCs can be designed with shielding to protect against EMI, which is crucial in avionics systems where signal integrity is paramount. This capability allows for the seamless integration of advanced technologies, such as radar systems and electronic warfare suites, without compromising performance. As military avionics continue to evolve, FFCs will play a pivotal role in enabling next-generation systems.

Flexibility and Customization

The flexibility of FFCs is another key benefit, allowing them to conform to complex shapes and tight spaces within aircraft. Unlike rigid cables, FFCs can be bent, folded, and twisted without compromising their functionality. This adaptability is essential for avionics systems, where space constraints and unique layouts are common.

Furthermore, FFCs can be customized to meet specific requirements, such as varying lengths, widths, and connector types. This level of customization ensures that they can be tailored to fit any avionics application, from cockpit displays to engine control systems. The ability to design FFCs to exact specifications enhances their versatility and broadens their potential uses in military aviation.

Future Prospects and Innovations

The future of FFCs in military avionics looks promising, with ongoing research focused on further enhancing their capabilities. Innovations such as embedded sensors and self-healing materials are being explored to add new functionalities. For instance, FFCs with integrated sensors could provide real-time monitoring of environmental conditions, improving system diagnostics and maintenance.

Another area of development is the use of advanced materials to improve thermal management and conductivity. As military avionics systems become more power-intensive, efficient heat dissipation will be critical. Future FFCs may incorporate nanomaterials or graphene to address these challenges, paving the way for even more robust and efficient avionics circuitry.

In conclusion, Flat Flexible Cable innovations are transforming military avionics circuitry by offering durability, space efficiency, high-speed data transmission, and customization. As technology advances, FFCs will continue to play a vital role in shaping the future of military aviation, ensuring that aircraft remain at the cutting edge of performance and reliability.

2025-08-09szshuoqiang -

Illuminate Your Space With High Quality LED Lights Long Lasting And Cost Effective Options

Are you tired of constantly replacing bulbs and dealing with high electricity bills? Discover how high-quality LED lighting can transform your environment with its exceptional durability and cost efficiency. This article explores the advantages of upgrading to LEDs, providing you with insights into why they are the smart choice for modern illumination needs.

Longevity and Durability

One of the standout features of LED lights is their impressive lifespan. Unlike traditional incandescent bulbs that may last only a year, LEDs can serve you for up to 25,000 hours or more. This means fewer replacements and reduced maintenance efforts over time.

Additionally, LEDs are built to withstand shocks, vibrations, and extreme temperature variations. Their solid-state construction makes them highly resistant to damage, ensuring reliable performance in various settings, from homes to commercial spaces.

Cost-Effectiveness and Energy Efficiency

LEDs consume significantly less energy compared to conventional lighting options. They convert most of the energy into light rather than heat, leading to lower electricity consumption and reduced utility costs. This efficiency can result in savings of up to 80% on your lighting expenses.

Though the initial investment might be higher, the long-term savings make LEDs a financially wise choice. Their extended lifespan and low energy usage mean you recoup the cost quickly, making them ideal for budget-conscious consumers seeking sustainable solutions.

Versatility and Environmental Benefits

LED technology offers versatile lighting options, including adjustable color temperatures and dimmable features. Whether you need bright task lighting or ambient mood settings, LEDs can be tailored to suit any space, enhancing both functionality and aesthetics.

Environmentally, LEDs are a greener alternative. They contain no toxic materials like mercury and are fully recyclable. By reducing energy consumption, they also help lower carbon footprints, contributing to a healthier planet for future generations.

2025-09-15tuiguang2 -

Imagine a bustling airport terminal, a symphony of rolling luggage, distant boarding calls, and the low hum of anticipation. Amidst this orchestrated chaos, a small, vibrant spot of color weaves an eager, bouncy path. It is a child’s first brightly colored suitcase—perhaps sunshine yellow, electric blue, or strawberry red—being pulled (or more accurately, enthusiastically dragged) by its tiny owner. This is not just luggage; it is a vessel. It carries more than clothes and a favorite stuffed animal. It is filled to the brim with dreams of roaring airplanes piercing the clouds, maps coming to life, and the thrilling unknown of new places waiting to be explored on a family vacation. This singular image captures a universal rite of passage, a moment where wonder and responsibility first intersect. The child is no longer just a passenger but an adventurer, their identity and aspirations literally packed into this handheld piece of the journey. The bouncing suitcase is a heartbeat of pure excitement, setting the rhythm for the entire trip to come.

The Suitcase as a Vessel of Identity and Autonomy

For a child, that first personal suitcase is far more than a practical item. It is a powerful symbol of growing up. Prior to this, their belongings were tucked into a corner of a parent\'s larger, more serious bag. Now, they have been entrusted with their own domain. The act of choosing what goes inside—the indispensable toy, the \"lucky\" shirt, the notebook for sketches—is an early exercise in curation and self-expression. Each item packed is a piece of their world they deem necessary for the adventure ahead.

This autonomy is profoundly empowering. Pulling the suitcase themselves, managing its wheels over cracks in the floor, and being responsible for its contents fosters a sense of ownership over the journey. They are not merely being taken on vacation; they are participating in it, contributing their own prepared kit for exploration. The bright color of the suitcase itself is a declaration. In a sea of black and navy rolling bags, this splash of neon green or polka dots is a beacon, shouting, \"I am here! I am going on an adventure!\" It marks their unique presence in the vast, impersonal space of the terminal.

The Airport Terminal: A Gateway to Enchantment

To the adult, an airport is a transit hub, often associated with lines, security checks, and delays. To the child pulling that colorful suitcase, it is a palace of wonders, the literal gateway to their dreams. The terminal is not a place to endure but the first fascinating destination of the trip itself. Every sight and sound feeds their imagination. The giant windows framing majestic airplanes are like viewing portals to another world. The suitcase bounces in rhythm with their pointed finger as they identify different airlines\' logos.

The sensory overload is magical. The robotic voice of the intercom announcing faraway cities sounds like an invitation. The slow parade of luggage on the carousel is a mesmerizing ballet. The diverse crowd—families, solo travelers, flight crews in crisp uniforms—paints a picture of a world in constant, exciting motion. Their suitcase, bouncing along, is their ticket into this grand narrative. They are not just observing; they are now part of the flow, their own little piece of luggage joining the great migration of people and dreams.

Dreams of Flight and Mechanical Wonder

Central to this entire experience is the airplane itself. Long before reaching the gate, the child’s mind is already in the clouds. The suitcase holds dreams of the moment the wheels leave the tarmac, that incredible sensation of power and lift that feels like magic. They dream of looking out the window at a landscape that transforms from a detailed map into a miniature patchwork quilt, with rivers like silver threads and clouds as fluffy islands.

The airplane represents the pinnacle of human ingenuity to a young mind. The suitcase bouncing through the terminal is, in a way, a ground-bound imitation of the journey its owner is about to take. Its wheels on the tile mimic the plane\'s wheels on the runway. Its sturdy shell protects precious cargo, just as the aircraft\'s fuselage does. In the child’s imaginative play, the terminal floor becomes a runway, and their journey to Gate B12 is a prelude to the real flight. Packed inside, next to the socks and shorts, are fantasies of visiting the cockpit, wearing a pilot\'s wings, and understanding the mystery of how such a heavy machine can soar.

The Anticipation of New Places and Family Bonding

While the airplane is the thrilling vehicle, the destination is the promise. The suitcase is filled with dreams of new places: the scent of salty ocean air different from home, the awe of seeing ancient castles or towering skyscrapers, the taste of unfamiliar and delicious foods. It carries the anticipation of sandy toes, museum treasure hunts, or the simple joy of a hotel room that becomes a secret basecamp. Each item packed is chosen with a scenario in mind—the swimsuit for the beach, the hiking shoes for the forest trail.

Most importantly, this journey is framed by the context of a family vacation. The bouncing suitcase signifies shared excitement. The child is likely chattering non-stop to parents or siblings about what they’ve packed and what they’ll do first. This shared anticipation strengthens bonds. The family unit becomes a team of explorers, with the child, through the ownership of their suitcase, feeling like a contributing member. The vacation is not something done for them, but with them, and their brightly colored luggage is the tangible proof of their partnership in the family adventure.

The Lasting Imprint of a First Journey

The memory of that first brightly colored suitcase bouncing through the terminal often outlasts the details of the vacation itself. It becomes a cherished mental snapshot, symbolizing a first taste of independence and the boundless optimism of childhood. The suitcase itself may eventually be outgrown, relegated to a basement or donated, but the feeling it represents remains.

In later years, traveling with standard, adult luggage, one might catch a glimpse of a similar scene—a small child with a lime-green or fire-engine-red case—and be instantly transported back. That image encapsulates a pure, unjaded excitement about the world and its possibilities. It reminds us that travel, at its heart, is not about logistics or Instagram photos, but about the dreams we pack, the wonder we feel, and the joyful, bouncing steps we take toward the unknown. The child’s suitcase, therefore, is more than an object; it is a moving portrait of hope, a compact capsule carrying the infinite weight of dreams on its tiny, spinning wheels.

2025-12-08dgdiwoli -

Imagine a Saturday morning: you\'re heading out for a weekend getaway, a brunch date, or perhaps a spontaneous adventure. Your outfit is perfect, your spirit is light, but there\'s one crucial element to complete your poised, ready-for-anything look—your beauty essentials, organized and within easy reach. This is where your perfect companion for weekends comes in: a mini makeup bag that is compact yet surprisingly spacious, designed to carry your favorite beauty items in style. In a world where mobility meets elegance, this little accessory solves a common dilemma—how to look effortlessly polished without lugging around your entire vanity. It’s not just a pouch; it’s a statement of practical luxury, a curated capsule for your confidence, ensuring that whether you\'re dashing from a café to an evening stroll, your signature lipstick, trusty concealer, and that perfect blush are always neatly stowed, protected, and ready to elevate your moment. This article delves into why this mini marvel is an indispensable ally for the modern, on-the-go individual, exploring its design ingenuity, organizational prowess, and the sheer style it brings to every outing.

The Art of Compact Design: Small Footprint, Big Impact

At first glance, the term \"mini\" might suggest limitations, but this makeup bag masterfully defies that notion. Its compactness is its greatest strength, engineered to slip seamlessly into the smallest of handbags, tote compartments, or even a clutch without adding bulk. Designers have meticulously considered every dimension, often utilizing structured yet soft materials that can expand slightly to accommodate contents while maintaining a sleek, slim profile. This isn\'t about squeezing things in; it\'s about intelligent design that respects the need for portability in our fast-paced lives.

Furthermore, the compact nature encourages mindful curation. Instead of overpacking \"just in case\" items that never get used, you are prompted to select only your absolute weekend must-haves—a process that is both liberating and efficient. The bag’s exterior, often crafted from durable, easy-to-clean fabrics like vegan leather, coated canvas, or high-quality polyester, ensures it remains pristine through your travels. Details such as a secure zipper, a sturdy pull, and perhaps a delicate tassel or metallic logo add a touch of sophistication, transforming a utilitarian object into a chic accessory that complements your personal style.

Spacious & Strategic Interior: A Place for Everything

Do not let the modest exterior fool you. Step inside, and you\'ll discover a thoughtfully organized interior that maximizes every square inch. Many of these bags feature clever multi-compartment designs. A main central cavity comfortably holds larger items like a pressed powder compact, a small moisturizer, or a travel-sized perfume bottle. Then, strategically placed mesh pockets, elastic loops, or zippered sections come into play.

These subdivisions are game-changers. The mesh pockets, often transparent, allow for instant visibility—perfect for lipsticks, eyebrow pencils, or makeup brushes, so you\'re not fumbling around. Elastic loops securely hold delicate items like makeup brushes or eyeliner pens upright, preventing caps from coming off and creating messes. A separate zippered compartment is ideal for smaller, precious items like jewelry, hairpins, or even a spare pair of contact lenses, keeping them safe and untangled. This level of organization means no more frantic digging; every item has a dedicated home, making touch-ups quick, clean, and utterly hassle-free.

The Weekend Edit: Curating Your Beauty Capsule

What truly brings this bag to life is the curated collection of beauty items it carries. A weekend demands versatility—your look might transition from a daytime exploration to a cozy dinner. This mini bag empowers you to pack a versatile beauty capsule. Think multi-purpose products: a creamy blush that can double as a lip tint, a tinted moisturizer with SPF, a mini eyeshadow palette with neutral shades, and a reliable mascara. The limited space inspires creativity and efficiency in your beauty routine.

Beyond color cosmetics, it’s also the perfect vessel for skincare saviors. A weekend away can be taxing on the skin. Tucking in a hydrating facial mist, a lip balm, a few sheet masks, or a sample-sized serum ensures you can maintain your skincare regimen on the go. The bag protects these products from spills, breaks, and the general chaos inside your larger bag. By holding this carefully selected edit, the makeup bag becomes more than a carrier; it becomes a personalized kit for maintenance and touch-ups that keeps you feeling fresh and confident from morning until night.

A Statement of Personal Style

In today\'s fashion landscape, every accessory is an expression of self. This mini makeup bag rises to that occasion beautifully. Available in a spectrum of colors—from classic black and nude to bold prints, pastels, or metallic finishes—it offers a way to showcase your personality. It can be a subtle match to your handbag or a vibrant pop of contrast. For many, pulling out a stylish, coordinated makeup bag feels like a small, personal luxury, a detail that completes an outfit.

The style extends to its functionality as a standalone accessory. On shorter outings, it can easily transition to being the only bag you carry, holding your phone, cards, keys, and of course, your lipstick. This versatility underscores its role as a true companion. It’s designed not just to hold your things, but to do so with an undeniable flair. Whether it’s perched on a vanity in a hotel room or peeking out of your tote at a café, it adds a note of considered elegance to your overall aesthetic.

The Ultimate Companion for Modern Life

Ultimately, this mini makeup bag embodies the principles of modern, streamlined living. It answers the call for products that are both beautiful and brilliantly functional. It declutters your routine, organizes your essentials, and travels with you effortlessly. For the busy professional escaping for a weekend, the student heading home, or anyone seeking a dash of organization in their leisure time, it proves to be an invaluable partner.

Its value lies in the peace of mind and confidence it provides. Knowing your essentials are neatly organized, protected, and instantly accessible allows you to fully immerse yourself in the joy of your weekend plans. It removes a layer of minor stress, letting you focus on the experiences and people that matter. In a small, stylish package, it delivers a significant upgrade to your daily rhythm, making it clear why this compact, spacious, and stylish bag is indeed the perfect companion for your weekends and beyond.

2025-12-12dgdiwoli

Latest Blogs

Can Laser Equipment Achieve High-Toughness Welds?

Imagine standing at the airport check-in counter, feeling a familiar pang of anxiety. Will your luggage be overweight? Is there enough space for that last-minute souvenir? Can you trust the lock to keep your belongings safe during transit? These common travel dilemmas are precisely what the Ultimate Travel Companion Trolley Bag Set is designed to solve. In an era where seamless journeys are as coveted as the destinations themselves, this innovative luggage collection promises to transform the very experience of travel. Combining thoughtful engineering with practical features like an expandable design, lightweight construction, and secure TSA-approved locks, this set isn\'t just about carrying your clothes—it\'s about carrying your peace of mind. Whether you\'re a frequent business flyer navigating tight connections or a family embarking on a long-awaited vacation, this set positions itself as the holistic solution for modern, efficient, and stress-free travel.

The Art of Intelligent Packing: The Expandable Design

At the heart of the Ultimate Travel Companion Trolley Bag Set lies its ingenious expandable design. This is far more than a simple zippered gusset; it represents a fundamental shift in packing flexibility. The main compartment features a robust, dual-zip expansion system that can seamlessly increase the bag\'s capacity by up to 25%. This means travelers can pack for a standard business trip and then, with a simple unzip, create ample room for unexpected purchases, bulkier items, or gifts for loved ones on the return journey.

The engineering behind this expansion is meticulous. The additional fabric is integrated seamlessly into the bag\'s structure, ensuring that when not in use, the profile remains sleek and streamlined for easy storage in overhead compartments or tight car trunks. When expanded, the bag maintains its structural integrity, preventing unsightly bulging or instability during transit. This feature effectively allows you to own two bags in one: a compact, carry-on compliant suitcase and a more spacious checked luggage option, all dictated by the needs of your specific trip. It eliminates the \"what if\" scenarios that often lead to overpacking a second bag or struggling with an overstuffed primary one.

Effortless Mobility: Lightweight Construction and Durability

A suitcase that is heavy when empty is a traveler\'s first misstep. The Ultimate Travel Companion set addresses this by prioritizing a lightweight construction without compromising on durability. The shells are crafted from advanced, high-density polycarbonate or premium lightweight polyester fabrics, materials chosen for their exceptional strength-to-weight ratio. This means the bags themselves add minimal weight, allowing you to maximize your airline\'s weight allowance for your actual belongings.

This lightweight philosophy extends to every component. The telescopic handle is made from reinforced aluminum or lightweight alloy, offering a sturdy, wobble-free extension while being easy to retract. The spinner wheels, a critical element for mobility, are crafted from durable, silent-roll rubber and are mounted on high-performance bearings. They rotate 360 degrees, enabling effortless navigation through crowded airport terminals, narrow airplane aisles, and uneven city pavements. The combination of a light frame and superior wheels reduces physical strain, making the journey from curb to gate noticeably less taxing, especially during tight connections or long terminal walks.

Security and Peace of Mind: TSA-Approved Locking System

In today\'s travel landscape, security is non-negotiable. The Ultimate Travel Companion set integrates built-in, TSA-approved combination locks into each piece of luggage. This system is a game-changer for international travelers. The Transportation Security Administration (TSA) and similar security agencies worldwide have master keys that can open these locks without damaging them. If your bag is selected for a physical inspection, authorities can open the lock, inspect the contents, and relock it, leaving your bag secure and intact.

The locks themselves are typically recessed into the bag\'s zipper system, making them resistant to tampering and accidental snags. They operate on a user-set combination, eliminating the hassle of carrying—and potentially losing—separate keys. This provides a robust layer of security against opportunistic theft while ensuring compliance with airport security protocols. Knowing that your possessions are safeguarded by a recognized standard, and that you won\'t arrive at your destination to find a cut lock or broken zipper from a security search, provides an invaluable layer of psychological comfort throughout your journey.

Thoughtful Organization and User-Centric Features

Beyond the core features, this trolley bag set excels in the details that streamline the travel experience. The interior is a masterpiece of organization. Multiple compartments, including mesh zip pockets, compression straps, and dedicated sections for shoes, toiletries, and laptops, help keep belongings orderly and prevent items from shifting during transit. This systematic approach saves time and frustration, allowing you to find what you need without unpacking everything.

Additional user-centric features abound. A waterproof laundry pocket separates soiled clothes from clean ones. The exteriors often include easy-access front pockets for passports, tickets, and smartphones. The materials are treated with stain-resistant and scratch-resistant coatings to maintain a pristine appearance trip after trip. The handles are ergonomically padded for comfort when the bags need to be lifted. Every aspect, from the smooth-gliding zippers to the reinforced corner protectors, is designed with the real-world challenges of travel in mind, creating a harmonious interaction between the traveler and their gear.

The Complete Travel Ecosystem: The Set Advantage

Offered as a coordinated set—typically including a large check-in suitcase, a carry-on trolley, and often a weekender or duffel bag—the Ultimate Travel Companion provides a unified travel ecosystem. Each piece is designed to work together, nesting within each other for compact storage at home. This modularity offers unparalleled versatility. You can use the carry-on for a short trip, combine the carry-on with the large suitcase for an extended holiday, or use the entire set for a comprehensive family relocation or long-term travel.

Investing in a matched set ensures consistency in quality, design, and handling. No more struggling with mismatched wheels or handles; every piece offers the same smooth glide, secure locking, and intelligent packing features. The cohesive look is also aesthetically pleasing, making your luggage easily identifiable on the baggage carousel. Ultimately, this set transcends being mere luggage; it becomes a reliable, integrated travel system that adapts to your lifestyle, empowering you to travel smarter, lighter, and with greater confidence, turning the journey itself into a more enjoyable part of the adventure.

Imagine stepping into an airport, train station, or hotel lobby with effortless grace. Your luggage glides silently beside you, its robust form undaunted by crowded corridors or hasty baggage handlers. Every essential item, from your laptop to your travel documents, is securely nestled in its designated pocket, accessible in an instant. This is not a scene from a distant, idealized future of travel; it is the immediate reality offered by the High Capacity Trolley Bag Set Built To Last. Designed explicitly for the modern, discerning traveler who values efficiency, durability, and intelligent organization, this luggage set transforms the often stressful chore of packing and transit into a seamless part of the journey itself. In an era where travel has become ubiquitous yet increasingly complex, the right equipment is no longer a luxury but a necessity. This set answers the call, promising not just to carry your belongings, but to enhance your entire travel experience through thoughtful engineering and rugged construction.

Uncompromising Durability: Engineered for the Long Haul

The cornerstone of any reliable luggage is its ability to withstand the rigors of travel. The High Capacity Trolley Bag Set is built with this principle at its core, starting with its reinforced corners. These critical stress points, often the first to fail on conventional suitcases, are fortified with additional, impact-resistant material. This design acts as a protective exoskeleton, shielding the main compartment from the bumps, drops, and crushing forces encountered during air travel baggage handling, tight car trunks, or storage in overhead compartments.

Beyond the corners, the entire construction speaks of resilience. The shell is crafted from high-density, scratch-resistant polymer or durable polyester blend, chosen for its optimal balance of lightweight flexibility and formidable strength. The zippers are not an afterthought; they are heavy-duty, self-repairing models with large, tactile pulls that glide smoothly even under full capacity. The telescopic handle system is another feat of engineering, constructed from reinforced aluminum or steel, ensuring it remains wobble-free and reliably extends and retracts through thousands of cycles. This is luggage that refuses to be a disposable commodity, instead positioning itself as a long-term travel companion for countless adventures.

The Symphony of Silence: Advanced Wheel Technology

Noise is the enemy of a smooth travel experience. The distracting, rattling clamor of cheap, hard plastic wheels rolling over tile or pavement adds an unnecessary layer of stress and announces your presence in every quiet terminal or hotel hallway. This luggage set eliminates that entirely with its advanced silent wheel system. The wheels are crafted from a high-grade, durable polyurethane compound, a material renowned for its quiet operation, smooth roll, and resistance to wear and cracking.

The design incorporates a double-spinner configuration, with four wheels that can rotate 360 degrees with minimal friction. This omnidirectional capability means you can glide the bag effortlessly alongside you, pivot through tight spaces with a gentle nudge, or navigate crowded areas with precision control—all in near-total silence. The wheel housing is also strategically designed to minimize the accumulation of hair, dust, and debris, which can cause squeaking and drag. The result is a feeling of effortless mobility that makes navigating vast airports or city streets a surprisingly pleasant part of the journey.

Intelligent Organization: A Place for Everything

For the smart traveler, time and accessibility are paramount. A chaotic suitcase where items are buried under one another is a recipe for frustration. This trolley bag set triumphs through its thoughtful array of multiple pockets and compartments, each serving a distinct organizational purpose. The interior is a masterclass in compartmentalization, typically featuring a dual-sided packing system with full-length dividers, compression straps, and zippered enclosures to keep clothing neatly separated and compressed.

The exterior organization is equally impressive. A dedicated, padded laptop sleeve protects your most critical electronic device. Multiple front-facing and side accessory pockets, often with RFID-blocking material, provide quick, secure storage for passports, boarding passes, phones, chargers, and water bottles. Some models even include a wet/dry compartment for separating toiletries or post-workout gear. This meticulous layout means you never have to unpack everything to find one item. Whether you need to breeze through security by quickly accessing your laptop or grab your boarding pass while in line, the design facilitates efficiency, allowing you to move with confidence and purpose.

Capacity Meets Practicality: Designed for Real-World Travel

High capacity must be paired with practical design to be truly useful. This set is engineered to maximize packing volume without succumbing to unwieldy dimensions. The main compartments expand strategically, often by an inch or two, providing that crucial extra space for souvenirs or bulkier items on the return trip, while still complying with most major airlines\' carry-on size limits for the primary bag. The companion pieces in the set are scaled to work together, offering a nested storage solution when not in use.

Practicality extends to every touchpoint. The ergonomic telescopic handle adjusts to multiple heights for comfortable pulling by travelers of different statures. The weight of the bags themselves is carefully considered, ensuring the durable materials do not add excessive heft before you even begin packing. Furthermore, the set often includes integrated TSA-approved combination locks, adding a layer of security without the hassle of separate keys. From weekend getaways to extended business trips, the design intelligently balances spacious interiors with a form factor that remains manageable and compliant with modern travel regulations.

The Smart Traveler\'s Essential Partner

Ultimately, this High Capacity Trolley Bag Set transcends its function as mere cargo carriers. It represents a holistic solution for the individual who views travel as an integral part of life—be it for business, exploration, or family visits. Its durability ensures it is a one-time investment that pays dividends over years, saving money and hassle. Its silent mobility preserves peace and reduces physical strain. Its intelligent organization saves time and mental energy, reducing pre-trip and in-transit stress.

In a market flooded with options, this set distinguishes itself by not excelling in just one area, but by harmonizing all critical aspects of luggage performance. It understands that the smart traveler demands gear that is as reliable, efficient, and adaptable as they are. By choosing this set, you are not just selecting luggage; you are opting for a more streamlined, confident, and enjoyable travel experience from the moment you pack to the moment you arrive back home. It is built to last, so you can focus on what truly matters: the journey ahead.

Imagine embarking on a long-awaited journey, only to be met with the frustration of a broken wheel on your suitcase, the anxiety of your belongings getting soaked in an unexpected downpour, or the chaos of rummaging through a single compartment to find a single item. For the modern traveler, these are more than minor inconveniences; they are disruptions that can overshadow the joy of exploration. This is precisely where the concept of a complete travel solution becomes not just a luxury, but a necessity. Enter the Complete Travel Solution Trolley Bag Set—a meticulously designed ensemble engineered to transform your travel experience from stressful to seamless. This set is not merely about carrying your possessions; it is a system built around the core principles of durability, protection, and intelligent organization. Designed to withstand the rigors of modern travel, it features robust water-resistant materials and strategically planned easy-packing compartments, promising to be a reliable partner from bustling city terminals to remote adventure trails. As we delve into its features, you\'ll discover how this set addresses the fundamental pain points of travelers, offering a holistic approach to packing and mobility that redefines convenience on the go.

Uncompromising Durability: Engineered for the Long Haul

The foundation of any reliable travel gear is its ability to endure. The Complete Travel Solution Trolley Bag Set is constructed with this principle at its core, utilizing high-grade materials designed to resist the common causes of travel wear and tear. The primary fabric is a reinforced, high-density polyester or similar polymer blend, known for its exceptional tensile strength and abrasion resistance. This means the bags can handle being shoved into overhead compartments, pulled across rough cobblestone streets, and loaded into cargo holds without succumbing to rips or tears.

Beyond the fabric, the structural integrity is reinforced at every critical point. The frames are typically made from lightweight yet incredibly sturdy materials like aircraft-grade aluminum or reinforced polycarbonate. These materials offer optimal rigidity to maintain the bag\'s shape while protecting contents from external pressure. The zippers are heavy-duty, often with self-repairing coils and large, easy-to-grip pulls that are lockable for added security. Corners, which are most prone to impact, are frequently fortified with protective bumpers or reinforced padding. This comprehensive approach to durability ensures that this bag set is not a seasonal purchase but a long-term investment, capable of accompanying you on countless journeys without showing significant signs of fatigue.

Superior Protection: The Water-Resistant Shield

While durability guards against physical damage, protection from the elements is equally crucial. The standout feature of this set is its integration of advanced water-resistant material. This is not merely a surface treatment but a fundamental property of the fabric, often achieved through techniques like polyurethane coating or laminated membranes. This creates a barrier that causes water to bead up and roll off the surface, rather than being absorbed.

This water-resistant capability provides peace of mind in a multitude of scenarios. It safeguards your belongings from sudden rain showers while navigating between airport terminals and taxis. It protects against spills in transit, be it from a leaky toiletry bottle inside or a beverage cart mishap nearby. For adventure travelers, it offers a defense against damp conditions, morning dew, or splashes during boat transfers. Importantly, this feature is balanced with breathability where needed, preventing internal condensation that can lead to mildew. The protection extends to the zippers as well, which are often backed by storm flaps or designed as water-resistant themselves, ensuring that moisture has no easy entry point. In essence, this feature transforms the bag set into a mobile, protective capsule for your valuables and essentials.

Intelligent Organization: Mastering the Art of Packing

A durable and protective bag is only as good as its usability. The Complete Travel Solution set truly earns its name through its thoughtful, easy-packing compartments. This design philosophy moves away from the chaotic, single-cavity \"black hole\" suitcase to a system of organized, dedicated spaces. The main compartments are frequently divided by removable compression panels or packing cubes, allowing you to separate clothing categories—shirts, pants, underwear—effortlessly.

Specialized compartments are strategically placed throughout the set. A dedicated, padded laptop sleeve in the carry-on protects your technology. Multiple interior lid pockets, some with clear vinyl windows, are perfect for documents, itineraries, or small electronics. Mesh pockets keep toiletries contained and visible, while zippered laundry bags separate worn clothes from clean ones. Externally, you might find quick-access pockets for items like passports, tickets, or a water bottle, eliminating the need to open the main compartment during security checks. This meticulous organization does more than just keep things tidy; it drastically reduces packing and unpacking time, minimizes wrinkles in clothing, and provides instant access to what you need, when you need it, making every stage of your journey more efficient and less stressful.

Ergonomic Mobility and Complete Set Synergy

The design excellence of this set extends to how it moves with you. The trolley bags feature multi-directional spinner wheels—typically four in number—that rotate 360 degrees. This allows for effortless maneuvering in tight spaces like crowded airport queues, narrow airplane aisles, or busy hotel lobbies. You can glide the bag alongside you with minimal pulling force, reducing strain on your arms and back.

The telescopic handle is another critical component, crafted from sturdy metal with a comfortable, non-slip grip. It should offer multiple height settings to suit users of different statures, ensuring an optimal, ergonomic posture while pulling. The handle mechanism is smooth and locks securely into place. The concept of a \"set\" is key here. Typically comprising a large check-in suitcase, a carry-on trolley, and often a versatile travel duffel or backpack, each piece is designed to work in harmony. They often feature a \"piggyback\" strap system that allows the smaller bag to securely sit on top of the larger one, freeing up your hands. This integrated system covers every travel need, from a weekend getaway using just the carry-on to an extended international trip utilizing the full set, all while providing a unified standard of durability, protection, and organization.

In conclusion, the Complete Travel Solution Trolley Bag Set represents a paradigm shift in travel gear. It transcends being a simple container by actively solving the perennial problems faced by travelers. Through its focus on rugged construction, it promises longevity. Its water-resistant nature provides a critical layer of defense against the unpredictable. Most importantly, its intelligent compartmentalization brings order and ease to the often-chaotic process of packing. When combined with smooth-rolling mobility and the synergistic design of a full set, it creates a holistic travel ecosystem. This set does not just carry your belongings; it carries your confidence, ensuring that you can focus on the experiences ahead, secure in the knowledge that your gear is reliable, protective, and effortlessly organized. It is, truly, a complete solution for the discerning traveler.

In an era where travel has become an integral part of our lives, the quest for the perfect luggage—one that combines durability, style, and intelligent functionality—is more relevant than ever. Enter the Away luggage collection, a brand that has redefined travel gear by focusing on the needs of the modern traveler. Designed to make every journey effortless, the collection promises not just to carry your belongings but to enhance your entire travel experience. With a philosophy centered on thoughtful design and robust construction, Away has garnered a loyal following among frequent flyers and casual vacationers alike. This article delves into the ultimate Away luggage collection, exploring how its durable materials and smart design features work in harmony to cater to every type of journey, from weekend getaways to global adventures. By understanding what sets this collection apart, you can discover why it has become a go-to choice for those seeking reliability and convenience on the road.

Unmatched Durability and Premium Materials

The foundation of the Away luggage collection lies in its commitment to using high-quality, durable materials that withstand the rigors of travel. Each piece is crafted from a polycarbonate hard shell, known for its exceptional strength and flexibility. This material is not only impact-resistant, protecting your belongings from bumps and drops, but also lightweight, ensuring that the luggage itself doesn\'t add unnecessary weight to your load. The hard shell is designed to be scratch-resistant, maintaining its sleek appearance even after multiple trips. Additionally, the collection features anodized aluminum details, such as the telescopic handle and corners, which provide extra reinforcement and a premium feel. The zippers are made from durable, self-repairing materials, reducing the risk of snags or breaks during transit. This focus on robust construction means that Away luggage can endure everything from crowded airport conveyors to rough handling, giving travelers peace of mind that their investments will last for years.

Beyond the exterior, the interior materials are equally impressive. The lining is made from a high-performance, recycled polyester that is both soft and resistant to wear and tear. This fabric is easy to clean and helps keep your clothes organized and protected. The attention to detail extends to the stitching and seams, which are reinforced to prevent unraveling over time. By prioritizing durability in every component, Away ensures that its luggage collection is not just a temporary accessory but a long-term travel companion. This reliability is particularly valuable for frequent travelers who need gear that can keep up with a demanding schedule without compromising on performance or aesthetics.

Smart Design Features for Enhanced Convenience

Away luggage stands out for its innovative smart design features that address common travel pain points. One of the most notable elements is the built-in removable battery, which allows travelers to charge their devices on the go. This feature eliminates the hassle of searching for airport outlets or carrying separate power banks, making it easier to stay connected during long journeys. The battery is safely integrated into the luggage\'s design, with a dedicated compartment that meets airline safety regulations. Another key feature is the 360-degree spinner wheels, which provide smooth and effortless maneuverability in any direction. These wheels are made from a durable, high-grade rubber that glides quietly over various surfaces, from carpeted hotel floors to uneven sidewalks, reducing strain on the traveler.

The interior organization system is another highlight, designed to maximize packing efficiency. Compression pads help secure clothes in place, minimizing wrinkles and creating more space for essentials. Multiple pockets and compartments allow for easy separation of items, such as shoes, toiletries, and electronics, making unpacking a breeze. The exterior includes a discreet laundry bag for storing dirty clothes, keeping them separate from clean items. Additionally, the luggage features a TSA-approved combination lock, adding an extra layer of security without the need for external locks. These smart design elements work together to streamline the travel process, allowing users to focus on their journey rather than logistical challenges. By anticipating the needs of travelers, Away has created a collection that is both practical and intuitive, enhancing every step of the travel experience.

Versatility for Every Type of Journey

The Away luggage collection is designed to cater to a wide range of travel scenarios, ensuring that there is a perfect option for every trip. The collection includes various sizes, from compact carry-ons to large checked bags, each tailored to different needs. For short business trips or weekend escapes, the carry-on models offer ample space while complying with most airline size restrictions. Their sleek design and lightweight construction make them easy to handle in crowded airports or on public transportation. For longer vacations or family travels, the larger checked bags provide generous capacity without sacrificing mobility, thanks to their well-balanced structure and smooth-rolling wheels.

Beyond size, the collection offers multiple color and finish options, from classic neutrals to bold hues, allowing travelers to express their personal style. Special editions and collaborations with designers add unique touches, making the luggage a fashion statement as well as a functional item. The versatility extends to the accessories available, such as packing cubes, garment bags, and toiletry cases, which integrate seamlessly with the luggage for a cohesive travel system. Whether you\'re embarking on a solo adventure, a family holiday, or a business conference, the Away collection provides tailored solutions that adapt to your specific requirements. This adaptability ensures that travelers can rely on their Away luggage for any journey, knowing that it will meet their needs with efficiency and style.

Sustainability and Ethical Considerations

In today\'s world, sustainability is a growing concern for many travelers, and the Away luggage collection addresses this through its commitment to ethical practices and eco-friendly materials. The brand prioritizes the use of recycled components, such as the polyester lining made from recycled plastic bottles, reducing waste and environmental impact. The hard shell polycarbonate is also selected for its durability, which extends the product\'s lifespan and minimizes the need for replacements. Away emphasizes transparency in its supply chain, working with factories that adhere to fair labor standards and safe working conditions. This ethical approach ensures that the luggage is not only good for the traveler but also for the planet and the people involved in its production.

Furthermore, Away offers a repair program to extend the life of its products, encouraging customers to fix rather than discard damaged luggage. This initiative aligns with a circular economy model, reducing overall consumption and waste. The brand\'s packaging is designed to be minimal and recyclable, further lowering its carbon footprint. By integrating sustainability into its core values, Away appeals to environmentally conscious consumers who want to make responsible choices without compromising on quality or design. This focus on ethics and sustainability adds another layer of value to the collection, making it a thoughtful choice for travelers who care about their impact on the world.

User Experience and Community Engagement

The Away luggage collection is backed by a strong focus on user experience and community engagement, which sets it apart in the competitive travel market. From the moment of purchase, customers benefit from a seamless shopping process, with detailed product information and responsive customer support. The brand\'s website and retail stores are designed to be inviting and informative, helping travelers make informed decisions based on their needs. After-sales services, such as the warranty and repair program, provide ongoing support, ensuring that customers feel valued long after their initial purchase. This commitment to customer satisfaction fosters loyalty and trust, making Away a reliable partner for travel enthusiasts.

Away also cultivates a vibrant community of travelers through content creation and social media engagement. The brand shares travel tips, destination guides, and user stories, inspiring others to explore the world. Collaborations with influencers and travel experts help showcase the luggage in real-world scenarios, highlighting its practicality and style. By building a sense of belonging among its customers, Away transforms its products into more than just luggage—they become part of a shared travel journey. This community-oriented approach enhances the overall appeal of the collection, as users feel connected to a larger narrative of adventure and discovery. Through these efforts, Away not only sells luggage but also promotes a lifestyle of effortless and meaningful travel.

Imagine stepping off a long-haul flight, weary but excited, only to find your luggage battered, a wheel stubbornly stuck, and your phone battery dead just as you need to navigate a new city. This all-too-common travel nightmare is precisely what the innovative brand Away set out to eliminate. Their philosophy is simple yet revolutionary: transform luggage from a mere container into a reliable travel companion engineered for seamless, stress-free journeys. At the heart of this mission lies a trio of groundbreaking features: virtually unbreakable shells, incredibly smooth-gliding wheels, and integrated, removable battery chargers. This article unpacks the multifaceted benefits of Away luggage, demonstrating how these thoughtfully designed elements converge to create a travel experience defined by durability, effortless mobility, and constant connectivity, ultimately empowering adventurers to focus on the journey itself.

The Fortress on Wheels: Unbreakable Shells for Unwavering Peace of Mind

The foundation of stress-free travel is confidence in your gear\'s ability to survive the journey. Away luggage addresses the primal fear of damaged belongings head-on with its focus on exceptionally durable shells. Constructed from premium, aerospace-grade polycarbonate, these hardside shells are engineered to be both incredibly strong and remarkably lightweight. The material possesses a natural flexibility that allows it to absorb impacts—be it a rough baggage handler\'s toss or an unexpected bump in the airport terminal—by flexing and then snapping back into shape, rather than cracking or shattering under pressure.

This resilience translates directly into peace of mind. Travelers no longer need to watch with bated breath as their suitcase tumbles onto the baggage carousel or worry about fragile souvenirs making it home intact. The hard shell also provides superior protection against the elements and compression, keeping clothes neatly pressed and dry. Furthermore, the sleek, scratch-resistant finish maintains its sophisticated appearance trip after trip, ensuring your luggage looks as good as it performs. This combination of brute strength and elegant design means you invest in a piece that is built to last for countless adventures, making it a sustainable choice that reduces the need for frequent replacements.

Effortless Navigation: The Engineering Behind Smooth, Silent Wheels

Mobility is where the travel experience truly begins and ends, and Away’s signature 360-degree spinner wheels are a masterclass in engineering. Unlike the clunky, noisy, and often wobbly wheels found on conventional suitcases, Away’s wheels feature a proprietary, high-performance design. They are mounted on a durable, sealed bearing system that ensures buttery-smooth rotation in any direction with minimal effort. Whether you\'re navigating crowded airport corridors with quick, agile turns, rolling over cobblestone streets in a historic European town, or maneuvering through a cramped hotel room, the suitcase glides silently beside you as an extension of your body.

The practical benefits of this seamless mobility cannot be overstated. It drastically reduces physical strain, eliminating the need to drag or lift a heavy bag over curbs and thresholds. This is particularly invaluable for connecting flights, long walks to distant gates, or exploring destinations on foot. The smooth roll also means no loud, disruptive clacking—a small but significant courtesy in quiet spaces. This effortless glide empowers travelers to move with speed and agility, turning what is often a cumbersome chore into a graceful part of the journey itself, conserving energy for the adventures that await.

Power On The Go: The Integrated Charger for Constant Connectivity

In our hyper-connected world, a dead phone battery can feel like being stranded. Away ingeniously integrates travel essentials by incorporating a removable, TSA-approved battery charger directly into the suitcase\'s design. Located in a discreet, exterior compartment, this 10,000mAh power bank can be easily slid out to charge devices on the go and is compliant with airline safety regulations when detached. This feature solves one of modern travel\'s most persistent headaches: the frantic search for an available outlet in a busy terminal.

The built-in charger ensures that your phone, tablet, headphones, or other USB-powered devices remain charged from door to door. You can land with a full battery, ready to use ride-sharing apps, digital boarding passes, translation tools, or camera without anxiety. The internal organization includes a padded laptop sleeve and compression panels, creating a cohesive ecosystem where your tech gear is both securely stored and perpetually powered. This seamless integration of power management transforms the suitcase from a passive holder of items into an active hub that supports your digital life, keeping you connected, entertained, and informed throughout your travels.

Holistic Design for a Streamlined Journey

Beyond these standout features, the true genius of Away luggage lies in how every component works in harmony to reduce travel friction. The interior is meticulously organized with compression pads, removable laundry bags, and discreet pockets, making packing and unpacking efficient. The patented, unbreakable zipper system adds another layer of security and durability. The telescopic handle, with its premium feel and multiple height settings, ensures a comfortable grip for travelers of all statures.

This holistic approach extends the concept of \"stress-free\" beyond durability and wheels. It encompasses the entire travel ritual. From the moment you pack, enjoying the satisfying click of the compression system, to the ease of gliding through a terminal, to the reassurance of having power at your fingertips, every touchpoint is designed for simplicity and reliability. The luggage becomes a trusted partner that handles the logistics, allowing you to immerse yourself fully in the experience of discovery. It represents a shift from merely transporting belongings to enhancing the journey, proving that the right tools can indeed make adventure more accessible and infinitely more enjoyable.

Popular Blogs

-

Advanced Mixing Tank Designs for Optimal Process Control

Effective mixing is paramount in numerous industrial processes, influencing product quality, reaction rates, and overall efficiency. Traditional mixing tank designs often fall short in achieving optimal process control, leading to inconsistencies and suboptimal outcomes. This necessitates the exploration of advanced mixing tank designs tailored for enhanced control and performance. This article delves into several key advancements in this field.Improved Impeller Design

Modern impeller designs are significantly more sophisticated than their predecessors. Instead of relying on simple axial or radial flow impellers, advanced designs incorporate features like multiple stages, pitched blades, and specialized geometries to optimize flow patterns and minimize dead zones. This results in more homogenous mixing and reduced energy consumption. Furthermore, computational fluid dynamics (CFD) simulations are increasingly used to design impellers specifically tailored to the characteristics of the fluids being mixed, maximizing efficiency and minimizing the formation of vortices or stagnant regions.

The integration of smart sensors within the impeller itself allows for real-time monitoring of mixing parameters, further enhancing process control. This data can be used to adjust impeller speed and other operational parameters dynamically, ensuring consistent mixing even with fluctuating process conditions.

Advanced Control Systems

Sophisticated control systems play a vital role in achieving optimal mixing. Traditional on-off controllers are being replaced by advanced process control (APC) systems, utilizing techniques like model predictive control (MPC) and fuzzy logic. These advanced systems can predict and compensate for process disturbances, maintaining consistent mixing quality even when faced with variations in feed composition, temperature, or viscosity.

Data analytics play an important role in these systems. By analyzing historical data from sensors and process parameters, the system learns the optimal operational strategies for different scenarios, continuously improving mixing performance and reducing waste.

Innovative Tank Geometry

The geometry of the mixing tank itself can significantly influence mixing effectiveness. Non-standard tank shapes, such as those with baffles strategically placed to redirect flow, or tanks with integrated recirculation loops, can improve mixing efficiency compared to traditional cylindrical tanks. The design of the tank bottom and inlet/outlet configurations also impact the overall flow pattern and mixing performance.

Further advancements include the incorporation of specialized internal structures within the tank, such as static mixers or helical flow elements, to enhance the mixing process and reduce the need for high-powered impellers.

wzwanxi2024-12-30 -

Revolutionizing Industrial Processes with Modern Mixers

The relentless pursuit of efficiency and precision in industrial processes has driven innovation across various sectors. A key player in this advancement is the humble mixer, which has undergone a remarkable transformation in recent years. Modern mixers are no longer simple agitators; they represent sophisticated technological marvels, revolutionizing how industries create everything from pharmaceuticals to construction materials. This evolution impacts productivity, quality control, and sustainability, offering a significant competitive advantage to those who embrace them.Enhanced Mixing Efficiency and Speed

Traditional mixers often struggled with achieving homogenous mixtures, leading to inconsistencies in the final product. Modern mixers, however, utilize advanced designs and technologies like high-shear mixing, planetary motion, and dynamic mixing systems to achieve superior mixing efficiency. These advancements significantly reduce processing time, leading to increased throughput and lower operational costs. For example, in the food industry, this translates to faster production of consistent batches of sauces or dough, meeting higher demands while minimizing waste.

Furthermore, the incorporation of sophisticated control systems allows for precise adjustments to mixing parameters like speed, torque, and temperature. This level of control ensures optimal mixing conditions for specific materials, resulting in superior product quality and consistency. Real-time monitoring and data logging also enhance quality control and facilitate process optimization.

Improved Process Control and Automation

Modern mixers are increasingly integrated with automated systems, allowing for remote monitoring and control. This automation reduces the need for manual intervention, minimizing human error and enhancing safety in potentially hazardous industrial environments. Automated systems can also optimize energy consumption by adjusting mixing parameters based on real-time data analysis, leading to significant cost savings.

Sophisticated software interfaces provide users with real-time insights into the mixing process. This data-driven approach allows for continuous improvement, enabling operators to fine-tune parameters and optimize performance based on detailed performance analysis. Predictive maintenance capabilities, enabled by data analysis, minimize downtime and ensure efficient operation.

Enhanced Material Handling and Scalability